3.34 m

Max. print width

905 m² (243 boards)/hr

Max. productivity

up to 1200 dpi

Resolution

CMYK or CMYKck; optional white and clear

Colours

Transform customer satisfaction.

Brilliantly.

The EFI™ VUTEk® Q3h series high-speed hybrid flatbed/roll-fed inkjet printers provide the highest-quality imaging and flexible and versatile production-level printing that will change the way you delight your customers with every sign and display application. And they feature the most advanced high-speed automation options we’ve ever offered, which is critical with today’s labour issues and cost-reduction initiatives.

Book a Demo

Offer customers more high-value applications

Highlights

Versatile hybrid platform

Board, sheet, or roll-to-roll printing on media up to 5 cm thick. Industrial built for multiple-shift operation and 24/7 printing. Maintenance is limited and easy for maximum uptime.

Production-level printing

Eight rows of printheads for productivity up to 905 m² (243 boards) per hour. Embedded continuous print to maximise productivity and advanced automation options.

Brilliant print quality

Four or six colours plus optional white and clear ink, and multilayer printing. Print quality resembles offset printing, with low pile height, fine details, and smoothness throughout. 7pL droplets produce stunning images up to 1200 dpi.

LED technology

Extend your range of supported substrates, increase uptime, reduce operating costs, and move towards more sustainable production with low VOCs, lower energy consumption, and less waste and consumables.

Genuine EFI Inks

Specially formulated to print on rigid and flexible media, GREENGUARD Gold certified EFI VUTEk Q3h Series LED inks offer a wide colour gamut and high colour vibrancy, accurate spot colour, and neutral grey printing, as well as excellent solid colours, fine detail reproduction, and outstanding skin tone rendering.

Fiery Driven

Fiery® proServer Premium digital front end with colour management workflow and RIP optimised for EFI VUTEk printers.

Learn more >

High density rendering (HDR)

A unique, optional print algorithm for enhanced colour quality and density that does not affect print speed. Allows added colour gamut while remaining in four-colour mode.

Double-sided printing

Option that uses individual QR code scanning for image content and position. The three-point pin registration is used for sheeted media. Supports single- and dual-roll double-sided printing on the Production and Super Duty roll-to-roll units.

Clear ink

Optional clear ink can be used to enhance an entire image (full flood) or selected areas (spot) to add extra pop to colours or special effects to graphics. Prints in line with the other colours and provides a hard surface cure with a gloss finish.

Media edge guides

The optional media edge guides (MEG) keep warp-prone media flat. They are easy to access and adjust based on media thickness and width.

Media handling and automation options

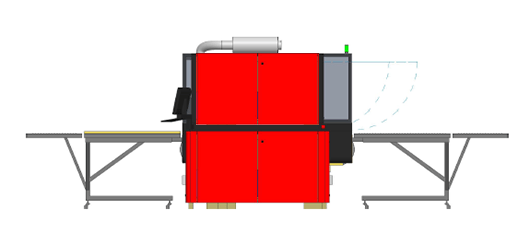

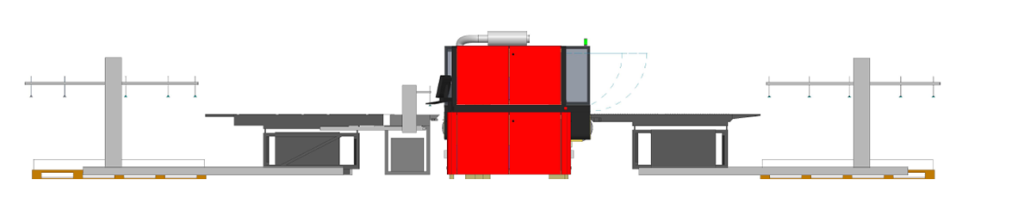

Manual loading and unloading

- Input and output tables for single or multiple board printing

- Available in 700 mm, 1650 mm, and 2150 mm depths

- Perfect for short runs or handling different types of media

- Optional 3-point alignment bar on the input table for easy and accurate media alignment; supports precise double-sided printing of thin or skewed media

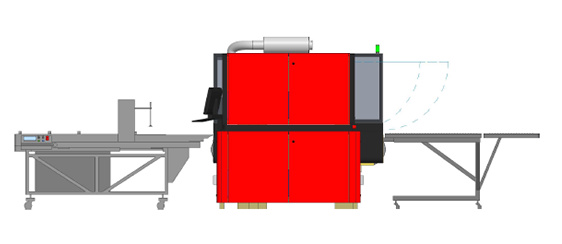

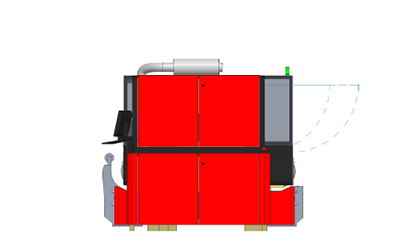

3/4 automated loading

Manual loading with automatic alignment and transport into the printer

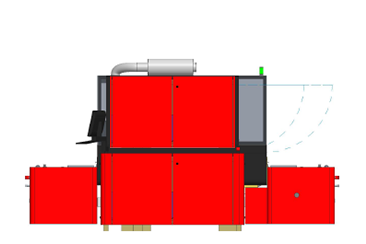

Manual loading with fully automated stacker

- Optional 3-point alignment bar on the input tables for easy and accurate media alignment

- Fully automated unloader/stacker

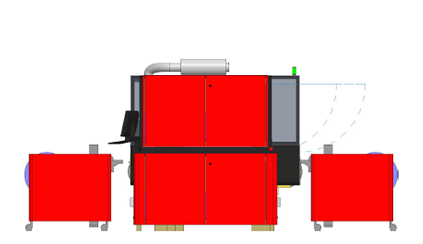

3/4 automated loading with fully automated stacker

- Manual loading with automatic alignment and transport into the printer

- Fully automated unloader/stacker

Full automation

- Automated loading and unloading

- For larger runs or runs with multiple board stacks

Light roll-to-roll

- Short to medium run, single roll-to-roll work

- Fast switchover between roll-to-roll and sheet mode

- Maximum weight of 200 kg per roll and diameter of 250 mm

- Can be combined with manual (un)loading tables and the automatic board feeder

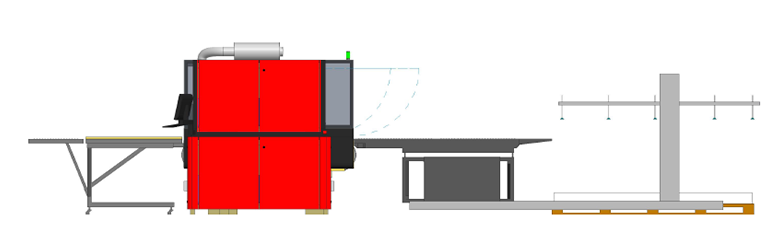

Production roll-to-roll

- Remains docked, allowing for fast changeover between rigid and flexible media

- Roll-to-roll or roll-to-floor printing

- Single- or dual-roll printing

- Maximum weight of 450 kg per roll and diameter of 400 mm

- Can be combined with manual (un)loading tables

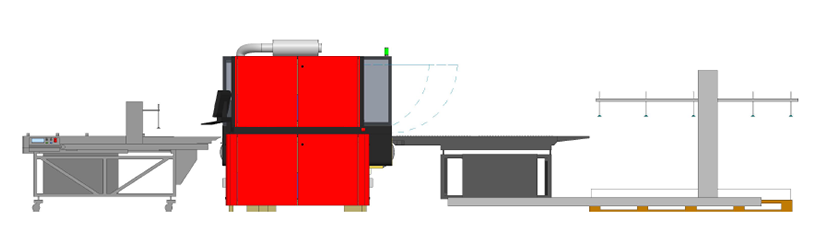

Super duty roll-to-roll

- Designed to handle very large and heavy rolls

- Roll-to-roll or roll-to-floor printing

- Single- or dual-roll printing

- Maximum weight of 700 kg per roll and diameter of 600 mm

- Dockable rolls for fast changeover between rigid and flexible media

- Can be combined with manual (un)loading tables and the automatic board feeder