348 cm

Max. print width

610 m2/hr

Max. productivity

up to 1200 dpi

True resolution

CMYK + optional white and clear

Colours

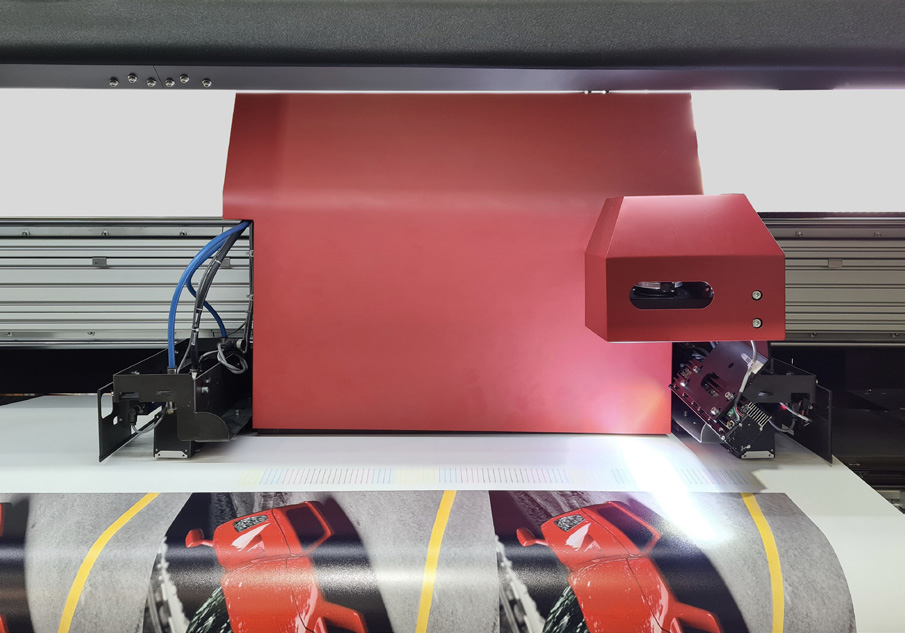

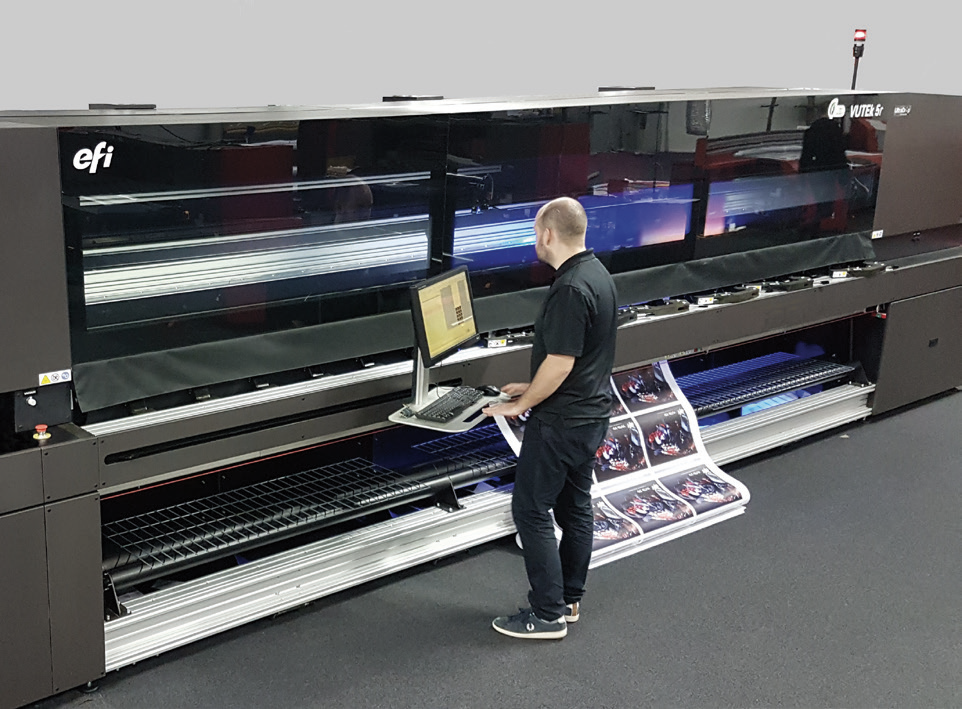

Engineered for high-volume production.

Built for your success.

The EFI™ VUTEk X3r® roll-to-roll LED printer is brilliantly engineered for high-volume production of indoor and outdoor sign and display applications. Carefully integrated automation, software, and hardware work together to support full-shift unattended printing, deliver a complete print-to-finished graphic workflow system, and take image quality at production-level speeds to a new level.

Book a Demo

Offer customers more high-value applications

Highlights

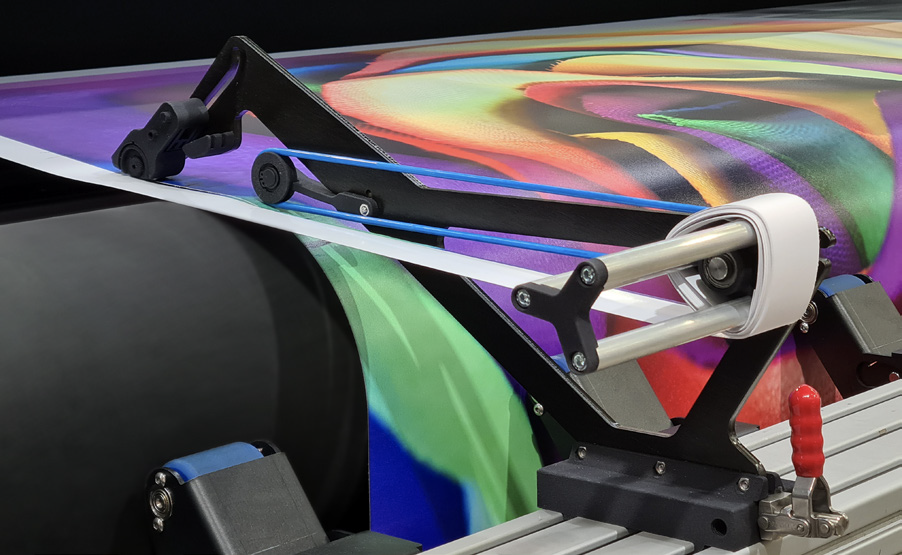

Production roll-to-roll printing

Quick and easy media loading that handles a wide variety of flexible substrates. Roll-to-roll, free-fall, and multi-roll

(2 rolls of 1.6 m).

High-quality imaging

Next-generation 5 pL printheads and up to 1200 dpi true resolution.

Industry-leading LED technology

Extend your range of supported substrates, increase uptime, reduce operating costs, and move towards more sustainable production with low VOCs, lower energy consumption, and less waste and consumables.

Inline finishing workflow

EFI’s unique roll-to-roll workflow automates the complete printing and finishing process on the fly and in a single system.

Minimal operator intervention

Full-shift, nearly independent operation is supported with in-line and offline verification of media roll length and ink tank levels, Wrinkle Analyser, and mobile operator alerts; Nozzle Compensation to monitor nozzle health, ensuring consistent print quality; and large and heavy roll media handling solutions for continuous printing.

Auto mesh printing

Optional automatic, full shift, non-stop continuous mesh printing reduces mist and overspray, and the need for operator intervention.

White ink and multilayer printing

Superb white ink printing performance in single- and multi-layer print modes.

EFI UltraClear Coat

EFI UltraClear Coat can be used for decorative applications and as a final protective coating, with up to a five-year limited warranty. It prints inline, simultaneously with the image, saving time versus using a separate offline coating system, and in gloss or matte finishes.

Watch video >

White and clear ink together

White and UltraClear Coat inks print together for increased design and application possibilities.

Ink for a super range of applications

EFI – 3M™ SuperRange UV LED Ink offers a hard surface cure, a wide colour gamut, excellent adhesion properties, and the industry-leading 3M™ MCS™ Warranty1 when printing with cobranded EFI and 3M UV LED inks on 3M flexible media.

Fiery Driven

Fiery® proServer Premium digital front end with colour management workflow and RIP optimised for EFI VUTEk printers.

Learn more >

1 Testing in progress.

Power Tools to boost your capabilities and profits

Y-slitter – for the vertical trimming of margins or slitting media into multiple jobs, minimising media waste and increasing the printing area.

- Simultaneous printing and media cutting on the Y-axis

- Modifiable configurations include:

- Single-bladed for trimming margins

- Double-bladed for slitting of single media into two jobs (blades are fixed 8 mm apart)

- Simple and easy installation with no tools required

- Easy manual adjustment of the slitter position along the printer table

- Retractable blades for maximum safety

- And waste collectors to roll up trimmed remnants, increasing overall productivity and eliminating the mess

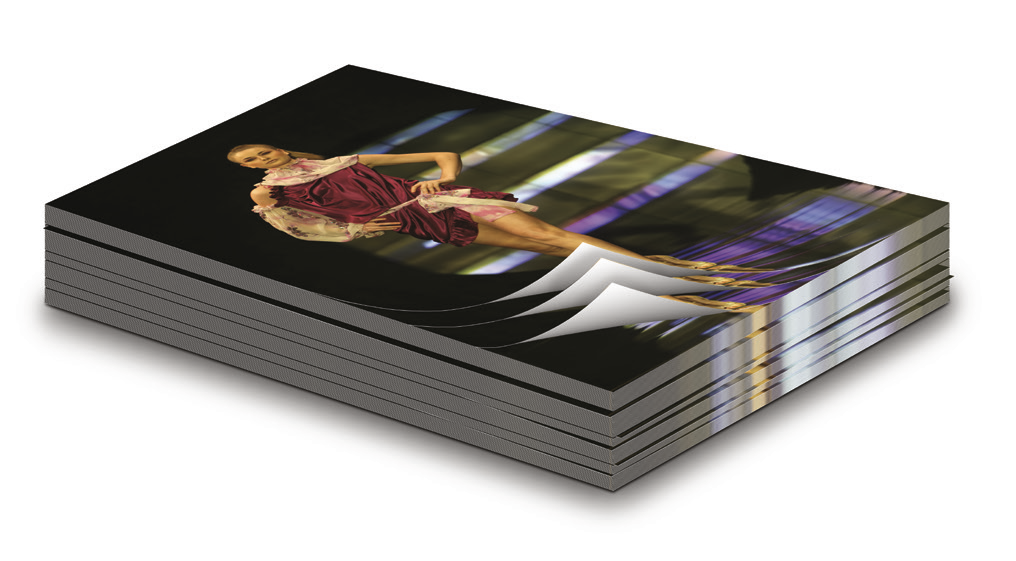

X-cutter – unique roll-to-sheet horizontal cutter incorporated in the printer.

- Automatically cuts media on the X-axis between jobs on the fly

- Controlled via the front-end software

- Does not affect productivity

- Saves valuable time at the finishing station

- Replaces expensive cutting equipment and saves space

- Prevents finishing errors and increases yield

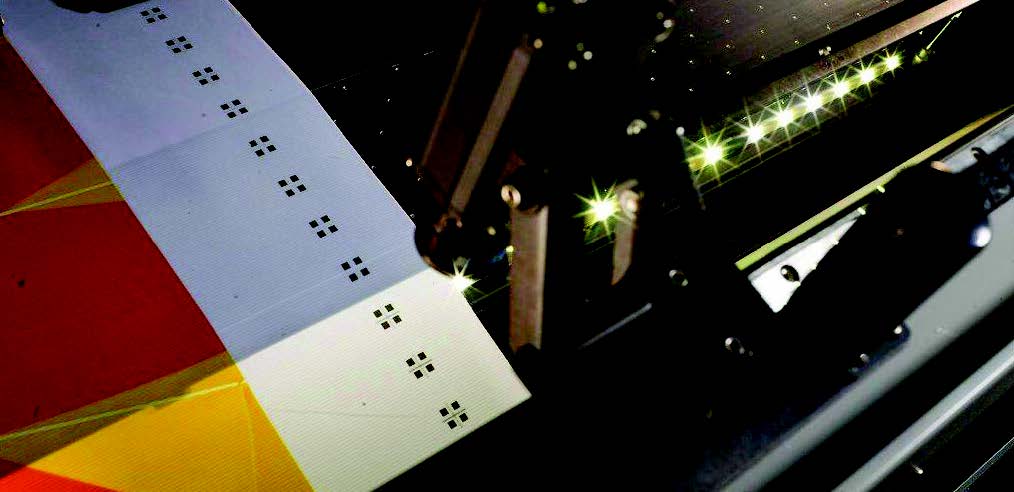

InSpec – vision system installed on the print carriage that performs automatic inline print quality monitoring for single and multi-roll printing. Includes a camera and light source as well as dedicated electronics and software. Designed to identify print imperfections in real-time during the print process, fix them when possible, and alert the user.

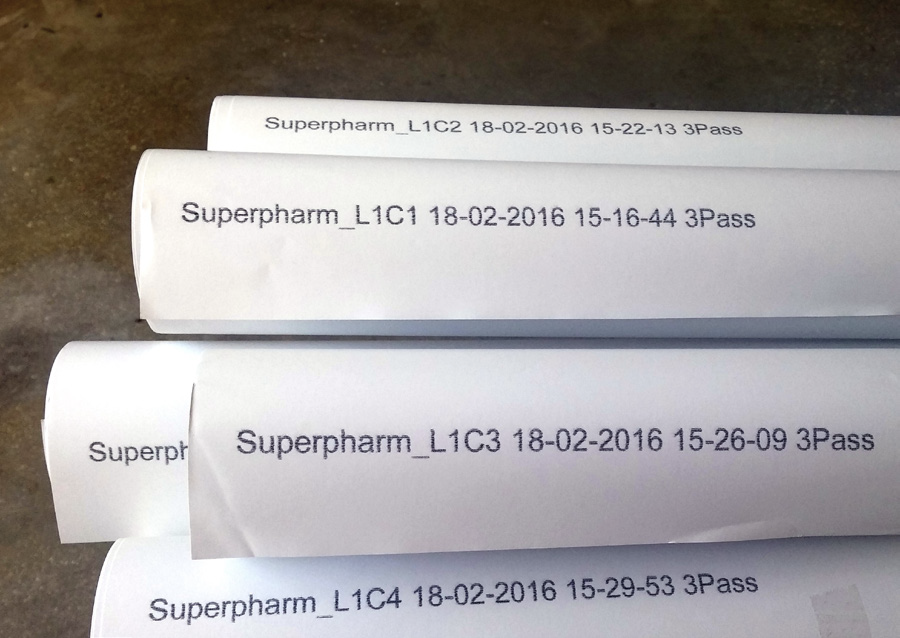

ID backprint – a device that prints file information on the back of the media, facilitating the identification of finished jobs for packing, shipping, and installation.

- Printed data includes:

- File ID

- Printing date and time

- Print mode

- Copy number and more

- Eliminates the need for manual labeling

- Helps prevent shipping errors

- Saves time during installation of the printed job

Automatic blockout printing – an automatic system that enables printing on both sides of opaque blockout media, resulting in excellent registration between sides.

- Accuracy of ≤ 5 mm over 10 linear metres

- Includes an optical sensor system, dedicated electronics, and software

- Simple, easy, and fully automatic system

- Eliminates the need for guesswork and manual manipulation

- Reduces required operator skill level

- Two available workflows, to be defined before printing:

- Head-to-head printing for short jobs where media is rolled back, flipped over, and reinstalled with side B up

- Head-to-tail printing for longer jobs where printed media is collected on a front core, flipped over, and reinstalled with side B up

Notes

- Single-roll printing for side B

- Use of X-cutter and Y-slitters with automatic blockout is limited:

- Slitters – possible according to built-in instructions

- Cutter – can be used for side B

Automatic backlit printing – Automatic, patented system for perfectly aligned double-sided backlit printing on backlit media.

- Accuracy of ≤ 2 mm over 310 linear metres

- Camera-guided software automatically correct registration on x, y, and tilt axes

- Includes two cameras, LED strip along printing table, and dedicated software

- Simple, easy, and fully automatic system

- Eliminates the need for guesswork and manual manipulation

- Reduces required operator skill level

White printing

- Enables printing on coloured and transparent media

- Opens up a myriad of creative possibilities

- Instant uptime of white printheads, thanks to the advanced circulation system in the ink tanks and along the entire ink system

- Multiple white print modes for various challenging applications:

- White only

- White as background

- White on top of colour

- White for backlit applications (C-W-C)

- Five-layer printing (C-W-B-W-C) for blockout printing on clear

- Various additional three- and five-layer print modes

UltraClear Coat

- Printed inline, simultaneously with the image

- Printed on top of the colour layer

- Enhances the output, adding extra pop to the colours and offering beautiful creative possibilities

- Full flood or selective

- Glossy or matte finish with the same ink

- Provides three years of outdoor protection against:

- Abrasion and scratching

- Chemicals such as detergents, gasoline, and IPA

- Weather damage

- Air pollution

- UV fading/yellowing

- Saves time versus separate offline coating systems

Mesh printing options for faster, easier, and cleaner ways to print on mesh and other porous substrates.

Integrated mesh kit – included with the printer.

Auto mesh system – optional Power Tool:

- Full-shift, continuous mesh printing

- Reduces mist and overspray

- Decreases operator labor

- Four user-defined blotter speed levels

Note: Consumable blotter paper supplied by EFI.

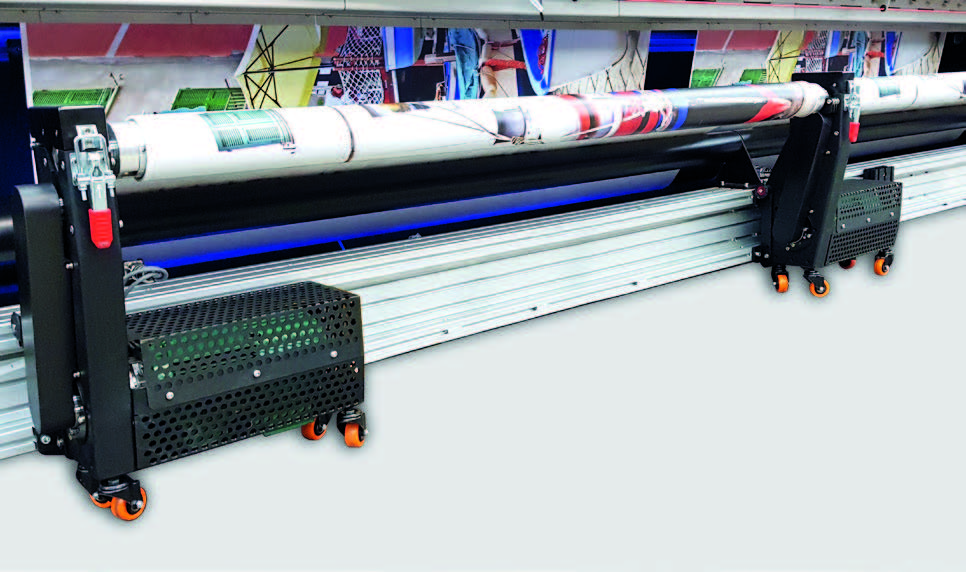

Motorised winder – integrated winder and unwinder solution with motorised pneumatic inflatable core shafts for precise and excellent media collection.

- Improves media advancement and print quality

- Allows using larger and heavier rolls

- Supports full printer width media as well as multi-roll printing:

- 2 x 1.6 m units for 3 m printer models, front/back

- 3 x 1.6 m units for 5 m printer models, front/back

Media spreaders – a pair of clamp-like devices that stretch the media sideways to enable neat media inlet to the printer.

- Helps prevent potential media wrinkles

- Improves media advance

- Facilitates printing on various types of challenging media

- Easy to install at both ends of the press beam on the rear of the printer

- Position and tilt angle are adaptable to the media type and width

Media edge guard (MEG) – used for media types with uneven or wavy edges that tend to curl or unravel, such as textiles and wallpaper.

- Designed to protect the print carriage and printheads from crashing into uneven media edges

- Eliminates ruined jobs and prevents media waste

- Can be attached quickly and easily with magnets anywhere along the printing table

- Use as many units as needed and multiple units for multi-roll printing

Three-metre super duty winder – fully integrated unwinder or rewinder option for EFI VUTEk roll-to-roll 3 m and 5 m printers.

- Enables working with heavy 3 m media rolls up to 793 kg

- Enables continuous, uninterrupted work without stopping to change rolls

- Increases productivity in high volume runs due to less make-ready

- Equipped with dancer and external motor

- Material width: 320 cm

- Maximum media diameter: 70 cm

- Standard 3 in core; optional 6 in core

Wrinkle analyser – helps avoid printhead strikes caused by media wrinkles, saving time and money by preventing ruined jobs and enabling the use of lower-cost media.

- Media height detector identifies a media wrinkle before it reaches the printhead

- The front-end software prompts the user to raise the carriage just enough to avoid a head strike that may ruin the job and, then, to resume printing

Mobile operator station – mobile workstation slides from its home position towards the middle of the printer.

- Saves the operator from moving back and forth between the station and the output

- Equipped with a touch screen for quick and easy operation

- Increases productivity and usability

Quality maintenance kit – enables printer operators to self-diagnose and fix print quality issues, including:

- Uncalibrated printer

- Missing or deficient nozzles

- Self-ownership and fast onsite reaction

- Minimises service visits and increases uptime

- Extends printhead lifespan up to 30% on average

- The optional system includes software and a dedicated scanner

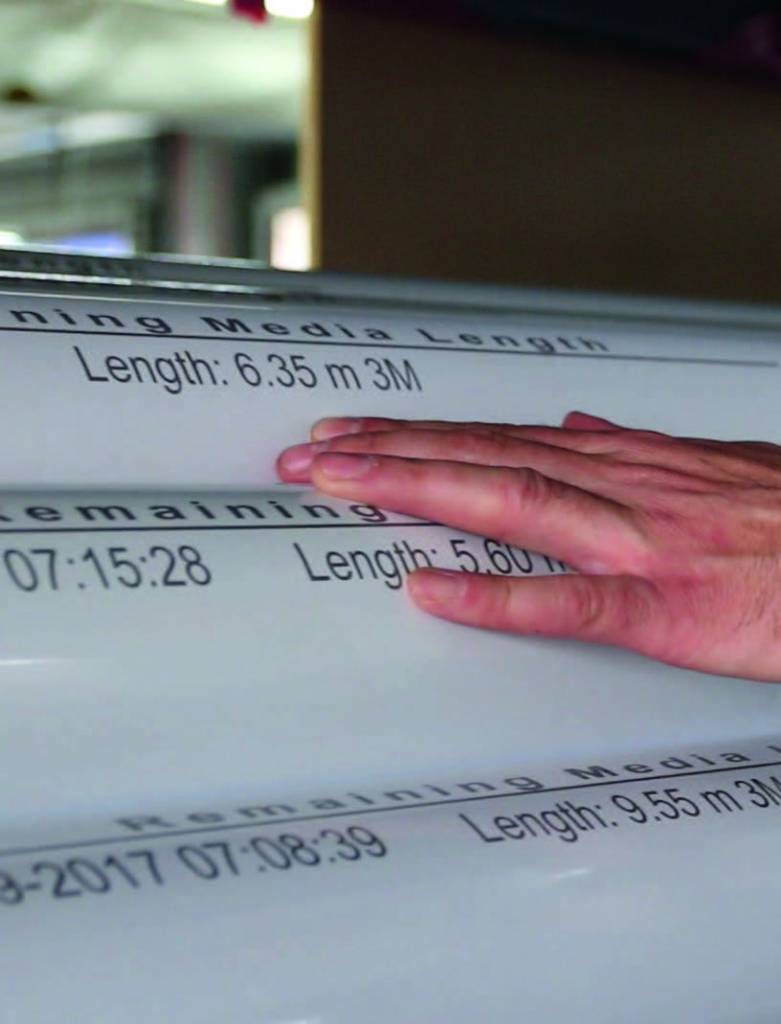

Media saving wizard

- Designed to improve media stock management

- The user enters the length of the media each time a new or partially used roll is loaded into the software

- Before the media is removed from the printer, a label with the remaining media length is printed on the rim of the roll

- The software will alert the user before starting a job if the remaining media on the roll is insufficient for the job

Resources

EFI VUTEk Xr Series Roll-to-roll LED Printers

The EFI VUTEk X3r and X5r roll-to-roll LED printers are engineered for the high-volume production of indoor and outdoor sign and display applications. Carefully integrated automation, software, and hardware work together to support full-shift unattended printing, deliver a complete print-to-finished-graphic workflow system, and take image quality at production-level speeds to a new level.