1372/2286 mm

Hanks size

132 kg/h (with ALS)

Max. production

320 sec

Cycle time

12 kg/cycle

Max. loading capacity

Maximum power for yarn treatment

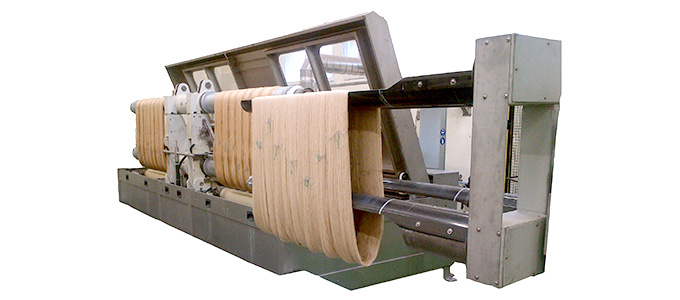

The EFI™ Jaeggli EXTENSA hanks yarn mercerizing machine features an electronic control and operating system along with a stretching force of up to 80 tons. This brings maximum flexibility, complete repeatability, and accurate evenness to every batch. The EFI Jaeggli EXTENSA utilizes an eco-block fixed-tank system, allowing you to use new soda at consistent parameters, and then recycle it through the all-in-one caustic preparation and recycling unit. The EFI Jaeggli EXTENSA mercerizing machine comes equipped with steel cases and automatic covers – and can be equipped with a manual or optional robotic loading system.

Book a Demo

Highlights

Yarn types

Cotton and all cellulosic fibres.

Eco-block system

All-in-one compact unit for the automatic preparation and supply of caustic soda lye to the machine. Strict parameters in the mercerizing process are easily controlled for consistent quality. Caustic soda lye preparation and continuous recycling provide on-demand water and soda recovery.

One system does it all

All-in-one system for filtration or microfiltration, soda, lye concentration regulation, wetting agent dosing, temperature control, cooling device by heat exchanger, and preparation for the supplementary chiller.

Eco-chiller

The Eco-block system comes ready for installation with a supplementary chilling unit that cools down the soda lye by means of cooled water through the heat exchanger.

Resources

EFI Jaeggli EXTENSA

The EFI Jaeggli EXTENSA hanks mercerizing machine offers high operational flexibility, easy repetitiveness, and absolute evenness.